Automatic CNC Machines: Revolutionizing Precision Manufacturing

In the dynamic landscape of modern manufacturing, Automatic CNC (Computer Numerical Control) machines have emerged as a pivotal force, transforming the way we approach precision and efficiency in production. This article delves into the intricacies of automatic CNC machines, exploring their evolution, applications, advantages, challenges, and future trends.

Introduction

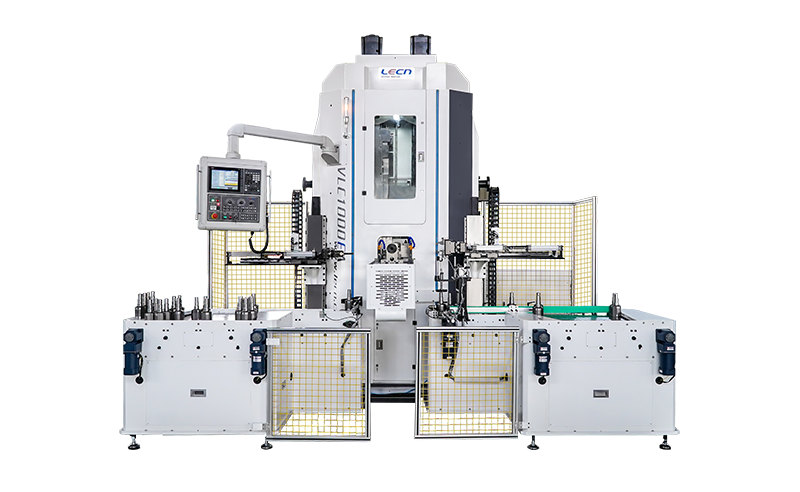

Definition of Automatic CNC Machines

Automatic CNC machines, a cornerstone of advanced manufacturing, utilize computerized systems to control and automate machining tools. These machines play a crucial role in achieving unparalleled precision and efficiency in various industries.

Importance in Modern Manufacturing

In an era where precision and speed are paramount, automatic CNC machines stand out as the backbone of modern manufacturing. From aerospace components to intricate medical devices, these machines are instrumental in shaping the products that define our technological landscape.

Evolution of CNC Technology

Early CNC Machines

The journey of automatic CNC machines traces back to the mid-20th century when the first numerical control (NC) machines were introduced. These early machines laid the foundation for the automation revolution that was to come.

Advancements in Automation

With rapid technological advancements, CNC machines evolved to integrate automation, allowing for more complex and intricate machining processes. The shift from manual control to automated precision marked a significant leap forward.

Integration of Artificial Intelligence

In recent years, automatic CNC machines have embraced artificial intelligence, enabling them to adapt, learn, and optimize operations in real-time. This integration has elevated the capabilities of CNC machines to new heights.

Key Components of Automatic CNC Machines

Computer Numerical Control

At the heart of automatic CNC machines lies Computer Numerical Control, where a computerized system interprets design specifications and translates them into precise machining instructions. This level of control ensures consistency and accuracy in the manufacturing process.

Motors and Drives

Efficient motors and drives are essential components that power the movement of cutting tools and workpieces. The synergy between these elements determines the machine's ability to execute intricate designs with utmost precision.

Tools and Tooling

The choice of tools and tooling systems significantly influences the versatility of automatic CNC machines. Various tools cater to specific materials and design requirements, offering manufacturers the flexibility to adapt to diverse production needs.

Featured content:Save Time and Money with a Pallet Wrapping Machine

SAST vs. SCA testing: What’s the difference?

Metal Parts Manufacturing - How to Make Custom Metal Parts

The Best Ways to Pack and Ship Machined Parts

Carbon Fiber Cost: Factors That Influence The Most

The Best Hair Straighteners, According to Celebrity Hairstylists and Vogue Editors

Revolutionizing Aquaculture: Dry-Type Fish Feed Extruder

Applications of Automatic CNC Machines

Precision Machining

One of the primary applications of automatic CNC Machining is precision machining. Whether crafting intricate parts for the automotive industry or producing components for medical devices, these machines ensure microscopic accuracy.

Mass Production

Automatic CNC machines excel in mass production scenarios, where the need for consistent quality and high output is paramount. The ability to replicate designs with minimal variation makes them indispensable in large-scale manufacturing.

Customization in Manufacturing

Contrary to the misconception that CNC machines are only suitable for mass production, they also facilitate customization. With advanced programming, manufacturers can tailor designs to meet specific requirements, catering to niche markets.

Advantages of Automatic CNC Machines

Precision and Accuracy

The inherent precision of automatic CNC machines eliminates human error, resulting in consistently accurate products. This level of precision is especially critical in industries where exact specifications are non-negotiable.

Increased Efficiency

Automation translates to increased efficiency, as automatic CNC machines operate tirelessly without the need for breaks. This not only speeds up production but also ensures a continuous workflow, contributing to overall productivity.

Reduction in Human Error

The automation of tasks minimizes the risk of human error, a significant factor in industries where the slightest deviation from specifications can have severe consequences. Automatic CNC machines mitigate this risk, enhancing the reliability of the manufacturing process.

In conclusion, automatic CNC machines have revolutionized manufacturing, offering unprecedented precision, efficiency, and adaptability. From overcoming challenges to embracing future trends, these machines continue to shape the landscape of modern production.

As we look ahead, the future of CNC technology holds exciting possibilities. Integration with IoT, enhanced machine learning capabilities, and a commitment to sustainability are driving forces that will further elevate the impact of automatic CNC machines.

Featured content:Revolutionizing Coffee Industry: The New Bean Grinder?

What is tube mill machine?

Advantages of Sheet Metal Laser Cutting Machine

Which tractor is best for hilly terrain?

Electric Scissor Lifts: Elevating Efficiency and Safety

How Do I Choose a Packing Machine?

What is co extrusion blow molding?

396

0

0

All Comments (0)

Previous: How to Build a 3D Welding Table

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments